A hole saw was used to cut the hole, starting on deck and cutting through about halfway then finishing the cut from under the deck drilling upwards. Cutting the hole from both sides prevents fragmenting the laminate as often happens when pushing through from one side.

Once the hole was made the Fein Multimaster was used to remove the core material between the laminate and the void was filled with a mixture of West System Epoxy and colloidal silica.

Once cured a drum sander was ran around inside the hole to clean up any epoxy spurs and ensure we had a uniform surface. The fitting was then bedded in 3M fast curing 4200.

The same method was used to cut the hole for the bulkhead compass. The notch at the bottom was cut out using a small flat blade on the Fein Multimaster tool.

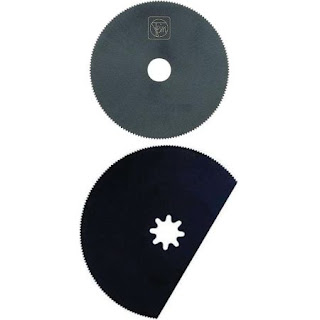

In response to the comment below and request for information; here is some pictures of the blades we have used in the MultiMaster tool.

The above blade we used to remove core materiel

The above blade was used to cut the lower portion of the compass hole

I really like the above blade with the flat portion. You can keep the flat edge very close to a shelf (for instance) and cut the bulkhead neatly and flush to the shelf.

We have found the scraper blade to be very fast at removing stubborn materiel. We used it a lot when re-coring portions of the deck to remove the balsa core and also on the hatches and window frames for removing old hatch gaskets and sealants.