A hole saw was used to cut the hole, starting on deck and cutting through about halfway then finishing the cut from under the deck drilling upwards. Cutting the hole from both sides prevents fragmenting the laminate as often happens when pushing through from one side.

Once the hole was made the Fein Multimaster was used to remove the core material between the laminate and the void was filled with a mixture of West System Epoxy and colloidal silica.

Once cured a drum sander was ran around inside the hole to clean up any epoxy spurs and ensure we had a uniform surface. The fitting was then bedded in 3M fast curing 4200.

The same method was used to cut the hole for the bulkhead compass. The notch at the bottom was cut out using a small flat blade on the Fein Multimaster tool.

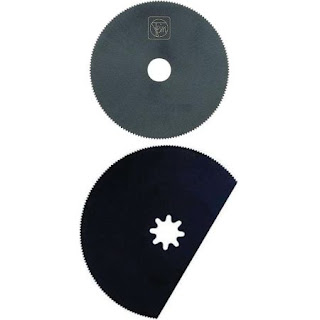

In response to the comment below and request for information; here is some pictures of the blades we have used in the MultiMaster tool.

The above blade we used to remove core materiel

The above blade was used to cut the lower portion of the compass hole

I really like the above blade with the flat portion. You can keep the flat edge very close to a shelf (for instance) and cut the bulkhead neatly and flush to the shelf.

We have found the scraper blade to be very fast at removing stubborn materiel. We used it a lot when re-coring portions of the deck to remove the balsa core and also on the hatches and window frames for removing old hatch gaskets and sealants.

3 comments:

I've really been enjoying the blog and reading the details of your progress. Thanks!

I finally bought my own Multimaster, and I am still figuring out what I can do and with which blades.

Can you tell me which blade that is you reefed the core out with (I can see it is circular, but can't tell which type it is)?

Also, if you don't mind, what flat blade did you use to cut the keyway in the compass hole?

Thanks ahead,

R.

Thanks!

We used the "MultiMaster Recessed Steel Saw Blade" (High speed steel for fiberglass, carbon fiber, 20 gauge sheet metal. Recessed to work flush to the surface)

Feins part # 6-35-02-144-014

For the "keyhole" at the bottom of the compass we used "MultiMaster Universal E-Cut Blades" (Designed to cut wood, plaster, drywall, synthetic & plastic material, and metal up to 1/32" thick. This blade is bi-metal construction and has a tooth pattern similar to standard hand held hacksaw blades.)

Feins part # 6-35-02-151-02-0

Cheers, Don

PS I will put up some pictures of the blades shortly.

Don,

Thank you so much - very helpful! In fact I just received a pack of the flexible scraper blades today and was using them - I only had the rigid type before... not so good on curves.

I sense there is so much more I could do with the MM, that I have not thought of yet, so I'm always eager to pick up tips.

R.

Post a Comment